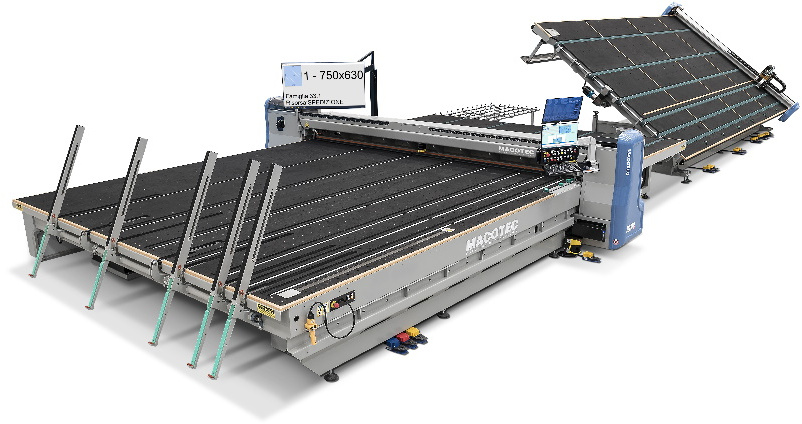

HP Linija z Avtomatskim Premikanjem

Ponuja avtomatizirano rezanje laminiranega stekla s 360° rotacijo, motoriziranim transportom in natančnim rezanjem z motorji, ki jih nadzira CNC. Ponuja avtomatski nadzor ločevanja, brisanje robov in enostavno vzdrževanje, kar zagotavlja visoko produktivnost in varnost.

2SKU:

N/A

Brand:

MACOTEC

Omogućuje automatizirano rezanje laminiranog stakla s rotacijom od 360°, motorizirani transport i precizno rezanje pomoću motora bez četkica kojima upravlja CNC. Sadrži automatsku kontrolu odvajanja, graviranje u obliku slova Z, brisanje rubova i jednostavno održavanje, čime se osigurava visoka produktivnost i sigurnost.

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.